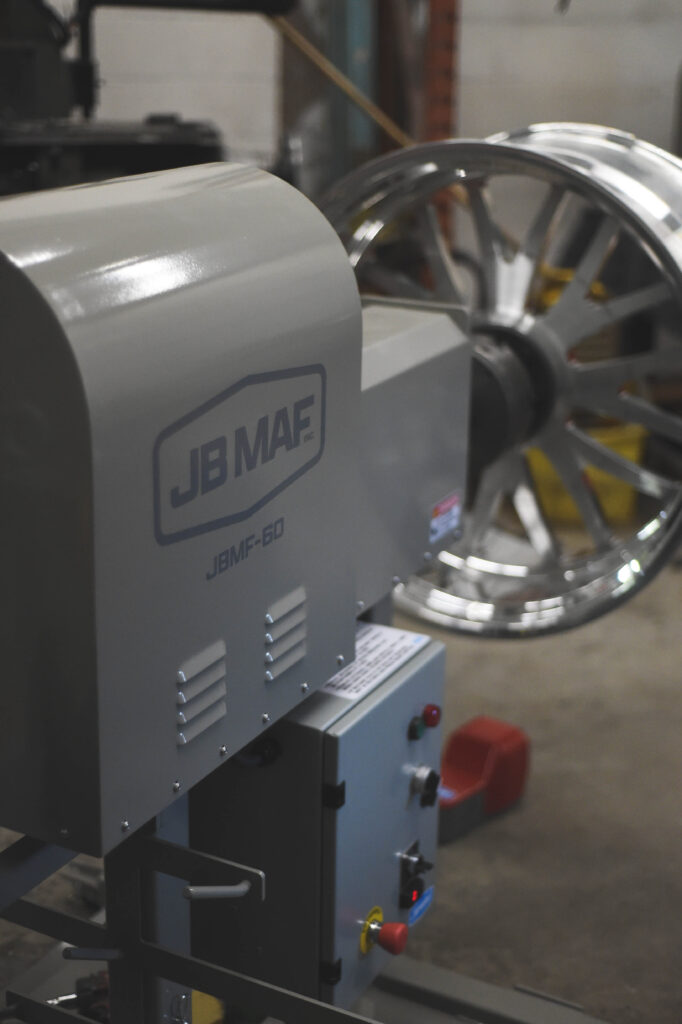

These robust workstations are essential for any busy wheel shop or wheel manufacturing facility. Operating on just 220 V single-phase power, these machines can easily be moved around the shop floor on their casters, positioned as needed, and securely lagged to the floor for safe operation. When no longer needed, simply retract the drop-down ear, remove the floor lags, and roll the machine back into storage.

Switch effortlessly between the extended jaws for holding large wheels up to 30” in diameter and the standard jaws, ideal for holding the various hubs available with these systems. A wheel center can be held safely in place, even during high RPM operations such as brushing. For an even finish on spoke surfaces, flip the rotation switch to reverse spin direction.

A mechanical brake holds your part steady during abrasive operations, and the foot pedal allows you to index your part forward, enabling continuous treatment of every spoke and surface without interrupting your workflow. The dual braking system ensures your part comes to a complete stop within seconds once the pedal is released, enhancing both efficiency and safety.

Our proprietary extended and adjustable jaws make attaching your wide range of wheel and wheel parts easy and safe. These precision machined components feature slip fit dowels to make repositioning fast and repeatable. These jaws have internal clamping and external clamping geometry allowing a variety of part shapes and styles to be attached.

Remove the extended jaws, and replace them with the factory jaws to use our extensive hub pack. If you are brushing/polishing or prepping machined faces, these hubs are the way to go. Holding the face from the lugs means you can access all areas of the wheel part. This is great when performing brushing operations, or deburring after CNC.

Our JBMF-100 and JBMF-150 ceramic polishing systems are robust, fully-automated machines that takes your aluminum alloy wheels and turns them to a high polished mirror finish. Our machines are designed and built entirely here in Waterloo, Ontario, Canada by our team. We only use the highest quality mechanical and electrical components. Lending from past European designs we have improved upon to create the best possible machine for operator experience, lean fluid/compound usage with consistent and reliable results.

These machines require 220 V single phase 15 amp service, with a 40 PSI regulated water source and drain. The internal PLC has preset modes that allows the operator to either run first, second or final stage media operations. Two dosing pumps run automatically to deliver accurate and lean ratios to the fluid nozzle head where clean water is mixed and fed into the bowl. Two drains allow spent water/compound to flow through the machine. Having this machine on your shop floor opens up a new income stream while maintaining the services you already have.

JBMF Machine Specifications

The JBMF-100 machine is our smallest product, sized with a 24″ diameter bowl that will allow you to polish wheels up to 21″. This machine is ideal for smaller parts, and typical sized car wheels.

The JBMF-150 is our largest machine, sized with a 30″ diameter bowl that will allow you to polish wheels up to 26″. This is ideal for larger aftermarket truck wheels such as American Force and associated brands. This machine also allows for the fixturing of larger parts such as valve covers, turbo housings, etc.

For further machine specifications, please contact us.

Results From Our Ceramic Polishing Process

The Ceramic Polishing Process

The process involved in transforming a wheel from raw aluminum to a high luster requires 3 stages. The first stage is the ‘cutting’ stage, with the most aggressive media and compound to work the surface of a wheel smooth. Second stage follows to further smooth the wheel’s surface and prepare it for the final stage. This 3rd and final stage involves ceramic media and a special compound formulation that produces the beloved polished finish!

Media and Compounds

We have dedicated a lot of research and time into creating the perfect process for ceramic polishing aluminum alloy wheels. We only use the highest quality plastic and ceramic media and compliment the process with specific liquid compounds. Whether you already have your own machine, or want to improve your Chinese machine to get better results let us help you. We are a distributor of Walther Trowal media and compounds which are the best products available, allowing you to get started the moment your machine arrives at your door.

Support and Training

We provide our customers with thorough user manuals and direct training to ensure they understand and get the most out of their JBMF system. For immediate support and consultation, we are available online to our customers 24/7.

Upon purchasing one of our machines, we offer in-person training where we fly to you and help you set up your machine. We are the only ceramic polisher manufacturer who uses their machine each day and have extensive knowledge about setting up the machine for wheels and other components. There is no guessing with us and our system! We have our processes down to a science.

JBMF-10 Liquid Dosing Station

Media and liquid compounds play the most important role in the ceramic polishing process. Using the highest quality consumables will ensure that you are getting the best surface finishes in the industry. At JB MAF we have created a process for our customers that makes their work easy, consistent and reliable. Often when off-shore equipment is purchased it comes without many vital components crucial to this process. We have created a fully automated liquid dosing station that controls your water flow and liquid compounds and introduces them into your bowl through our atomizer nozzles.

This retrofit kit mimics our proprietary dosing program that our flagship model JBMF-150 uses. You will be using half of the liquid compounds and water per cycle compared to all other systems on the market. Your margins as a business owner are primarily your liquid compounds so having a lean system to deliver those are vital to making money. With our simple control panel you will simply select the stage you want with the 3-position selector switch, and press run.